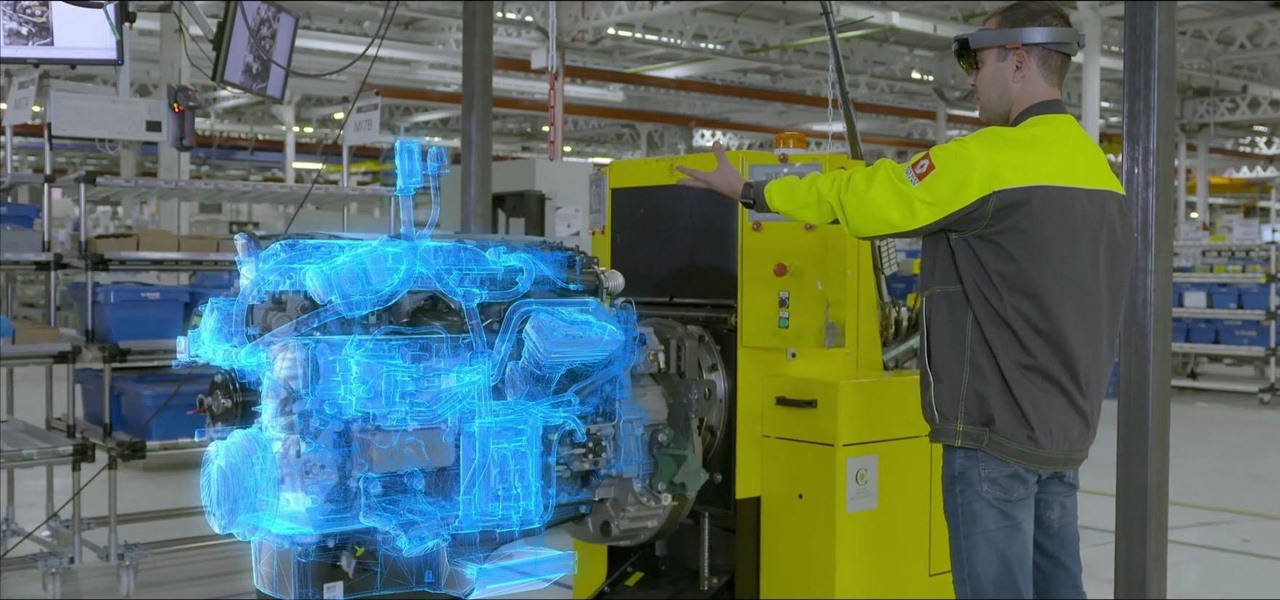

French manufacturer Renault Trucks is looking to the HoloLens to improve quality control processes with its engine assembly operations.

An internal incubation team of about 20 employees is collaborating with technology partner Immersion to design a prototype of the application, which is in testing at the company's Lyon-based facility.

"In practice, quality control operators will wear Microsoft HoloLens smartglasses in which all the digitalized engine parts will be integrated," said Bertrand Félix, an engineer at Renault Trucks who is leading the project, in a company statement. "Via the glasses and Mixed Reality interface, operators will see decision-making instructions that will guide them through the most complex control operations. At the moment, operators working on control points are still using paper instructions."

In recent times, we've seen many examples of industry applying augmented reality to reduce the "cognitive load" on employees and improve the efficiency of operations, including companies like GE Aviation and John Deere. In many of these cases, the technology is usually as a form of "assisted" AR, where technicians are fed process guidance and knowledge base information to their smartglasses display or share their view with remote experts to consult on an issue.

Renault and Immersion are taking a much more advanced approach. In this case, the HoloLens is used to overlay a digital model of an engine on top of the physical engine so workers can see how the machine should appear. Employees will also be able to see each part separately, with the software guiding them through each step of the quality control process.

"With Renault Trucks, we have designed and developed a tool that is perfectly suited to the requirements of the factory, which can be integrated into the manufacturer's industrial processes," said Jean-Baptiste de la Rivière, R&D and innovation director at Immersion.

Adopting AR will have an additional benefit for the manufacturer, as it will help the company move closer toward its goal of becoming a paperless workplace. Currently, Renault is targeting the 2019–2020 timeframe for deploying the technology across its entire manufacturing footprint.

Just updated your iPhone? You'll find new features for Podcasts, News, Books, and TV, as well as important security improvements and fresh wallpapers. Find out what's new and changed on your iPhone with the iOS 17.5 update.

Be the First to Comment

Share Your Thoughts